Portfolio

Portfolio

FREE Estimates | Senior DISCOUNTS Available | Licensed and Insured

FREE EstimatesSenior DISCOUNTS AvailableLicensed and Insured

Ventilation

Proper ventilation is essential for a roof to perform as long as it’s supposed to be. Without sufficient ventilation, an attic can overheat the shingles and cause premature cracking and burnout. In the winter, a properly vented roof will not create moisture or mold that can otherwise occur. Manufacturer's warranties are void if a roof is not installed with the proper amount of intake and exhaust ventilation.

Here is an example of one way to vent a roof using low profile eyebrow vents that are pre-painted for lasting color. These engineered vents are part of the Owens Corning system that will qualify a new roof for a 50-year non-prorated warranty when installed by an Owens Corning preferred contractor. Shown here is an Owens Corning Teak Duration TruDefinition composition shingle.

At Elite Roofing, we use large based flashings and vents for greater protection against high water flow. All flashings are painted to a corresponding roof color.

All flashings are replaced and painted.

This is an example of a ridge vent. A ridge vent allows for a ventilation system that spans the entire ridge area. After the ridge vent is installed, a high-profile ridge is installed over the ridge vent. This Owens Corning ridged ridge vent is also part of the Owens Corning system and is another component that can be used to qualify a roof for a 50-year non-prorated material warranty. Shown above is an Owens Corning TruDefinition Desert Tan composition roof.

The Owens Corning ridge vent is rated to vent 18-square inches of net free air per foot. Shown is an Owens Corning Driftwood TruDefintion composition roof.

Tile Roof Repair

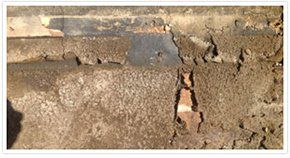

Improper installation of tile and underlayment can lead to underlayment deterioration and dry rot.

It is important to have tile roofs inspected and properly maintained to maximize their effectiveness and minimize problems due to debris build-up and breakage.

Once the underlayment on a tile roof has been breached, a "patch" is not sufficient and the leak is likely to reappear. It is important to remove and replace all of the underlayment that has been affected. At Elite Roofing, we use only upgraded fiberglass reinforced underlayment for optimum life and performance.

If the underlayment is not properly installed at the gable ends, deterioration and dry rot are likely.

Older tile valleys allow the tile to set directly on the metal creating a damning effect. This is compounded when debris builds up underneath the valley tile. Redwood bats, which the tile set on, also will catch water, divert sideways instead of allowing it to flow down to the gutter.

We use only upgraded wider 5 V raised valley metal that will raise the tile off of the valley and allow for great water flow. We also use engineered plastic pass through bats that allow water to flow through if a water diversion should occur which is very unlikely with the upgraded valley metal. Underneath, we use upgraded fiberglass reinforced and rubberized underlayment.

We also custom fabricate pan metal extensions. Pan metal, along with valleys, is the usual problem areas on a tile roof. Once a deterioration of the underlayment has occurred, the tile must be removed and the infected underlayment should be replaced.

Our family and locally owned business has done more tile and roof repairs than most big companies around! We offer fast services that won’t break that bank. Contact us

today and get an estimate right away.

Up to Seven Years of Workmanship WARRANTY!

Call 916-933-9609 / 530-676-3511

916-933-9609 / 530-676-3511

Quick Links

Our Service Area

Call Us Today

Contact Us

Elite Roofing

Shingle Springs, CA 95682

Primary Number:

916-933-9609

Alternate Number: 530-676-3511

Contact:

Darren Jonutz (Owner)

Mailing Address:

PO Box 1621

Shingle Springs, CA 95682

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2025

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.